Technologies

Technology

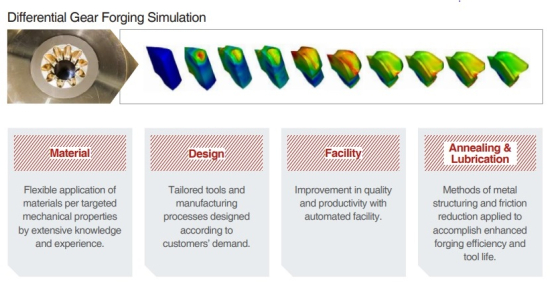

TRU Net Forging

To successfully deliver a competitive product to market, our world class engineers and forging facilities are fully operational

with robust tooling analysis and on-demand designing capabilities. DYNAMEC will never stop its efforts to create qualityoriented and market leading forging products.

Technology

H-Grade Precision Machining

DYNAMEC operates on an optimized machining line structure for the various materials including steel, aluminum, and

casting. Critical dimensions are fully controlled within operations by automated in-process measurement devices.

Technology

One-Stop Automated Heat Treatment

Line of heat treatment furnaces are automatically controlled for proper heat treatment condition. Experienced engineers’

inspection per batch completes the integrity of metallurgical structure and hardness of each heat treated products.

Technology

Firm-Thin Metal Plating

Plating facilities are automatically controlled for proper plating condition. Experienced engineer inspect it’s operating condition as well for guarantee product quality.

Technology

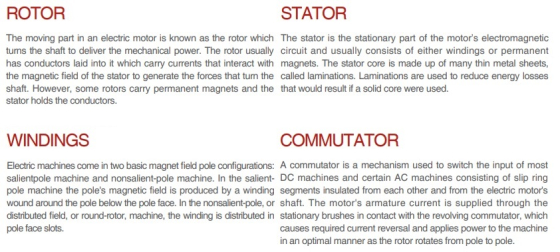

Light-weight Electric Components & Motors

DYNAMEC has the full capabilities to offer our customers the entire electronic manufacturing process- from coil preassembly to end-of-line testing. Our quality principles apply here as well; all under one roof. As a system integrator, we

control e-motor assembly and ensure top quality procedures, processes, and products.